4.0mm Tube Straightening Can™

Descriptions:

Our Straightening Can™ is applicable for various flexible tubes, such as copper tube, brass tube, aluminum tube or stainless steel tube. It is also applicable for automotive, plumbing, heating system, air conditioning system, and industrial piping.

Features:

- Art No.: 721105-40

- For 4.0mm(Outside Diameter) coil tube, as well as aluminum or stainless steel tube, light wall coiled tubing.

- 16 ball beared precision rolls, straighten the line without difficulty.

- Proposition 65(CA65) inspection document by SGS Taiwan are arrival (For USA market).

- Material of plastic parts: Poly-Carbonate(PC).

- Material of wheel: Aluminum alloy (T6061).

- Product weight: 600g.

- 100% Made in Taiwan

- Packing details:

- 10 PCS/Inner box

- 20 PCS/Carton

- N.W.: 12.4 KGS

- G.W.: 13.4 KGS

- CU'FT: 0.95

Offical Link:

Feature of Product

Our 4.0mm Tube Straightening Can™ is applicable

Our 4.0mm Tube Straightening Can™ is applicable for various flexible tubes, such as copper tube, brass tube, aluminum tube or stainless steel tube. It is also applicable for automotive, plumbing, heating system, air conditioning system, and industrial piping.

Shock - Proof Material Poly-carbonate

4.0mm Tube Straightening Can™ is made of Poly-carbonate which so as to be transparent and to obtain impact resistance, and operation of multiple rollers and a metal tube is visible because the Straightening Can™ is transparent. We hope this Straightening Can™ is not just a tool, but also has aesthetic appearance.

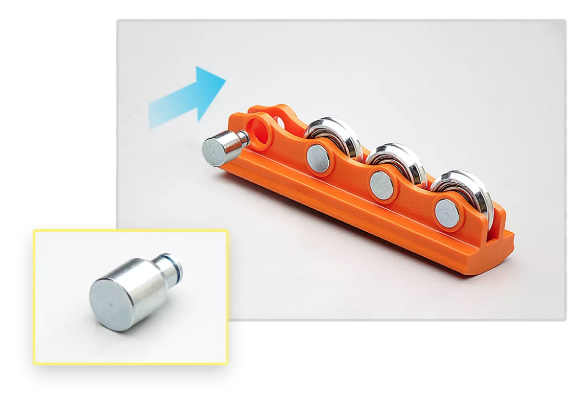

Roller Chutes

A plurality of roller chutes are made of Poly-carbonate in difference colors so as to distinguish Straightening Cans™ of various sizes. The plurality of roller chutes have impact resistances because they are made of Poly-carbonate so that a roller seat resists against pressure and does not deform, when the metal tube passes through the multiple rollers.

Our products are 100% made in Taiwan and The patent application numbers are as follows

TW I565542 / TW D188175 / US 9,862,015 B1 / EP 3272436 / CN ZL 2017 1 0157133.3

Metal Cap

Two caps made of metal are mounted on two openings of the 4.0mm Tube Straightening Can™ respectively so as to enhance quality of the straightening can and to avoid the copper metal tube scratching this can.

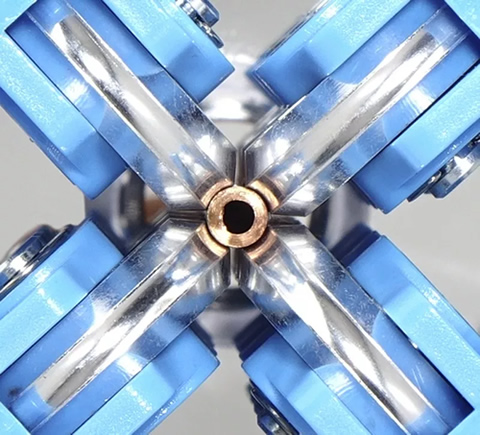

Aluminum Alloy Rollers

The rollers are made of aluminum alloy (T6061) and are anodized so as to avoid scratching the metal tube.

High - Performance Ball Bearing

A ball bearing made of steel is accommodated in each roller and it is applicable for the copper tube of a diameter of 4mm (1/8”) to 16mm (5/8”). The more diameter of the copper tube is, the greater pull force is required. To avoid scratching the copper tube when the metal tube passes through the can, the ball bearing is closed to reduce resistance, hence the copper tube passes through the roller smoothly.

Carbon Steel Bolts

A plurality of bolts made of carbon steel and electroplated are inserted through the ball bearings so as to fix the ball bearings and a groove holder. When the diameter of the bolts is approximately 10.0mm and the metal tube passes through the rollers, the bolts withstand greater pressure and are not broken or deformable.

Precision Curvature Of The Roller

The curvature of the roller will be different for the diameter of each metal tube. Some of the products sold on the market are a roller of a specific curvature suitable for different sizes of metal tubes. But such a physical condition is not perfect for the roller. In order to ensure that the metal tube completely contact with the roller, we use a roller of specific curvature to match with the metal tube of each size to ensure that the metal tube tightly contacts with the roller, and the metal tube does not deform or is not scratched when passing through the roller.

Matched Diameter Of Pipe Absolutely

As shown in this figure, the roller matingly contacts with the metal tube. This is no match for the products sold on the market today.

Size Changeable Design

Our products can be used with metal tubes of different diameters by replacing 4 sets of pulleys at a time. This innovative structural design allows us to have more applications and can also be sold with sets, which is not a function of similar products currently sold on the market.

15 Standard Colors

We have 15 standard colors, which are used in the roller chute to distinguish the different sizes of our products. We use color as a size management, letting the user see the color and know which size it is. This unique feature is something you have never seen before compared to other tools sold on the market.

laser Marked

In marking of the size and the logo of the product, we mark the size and the logo onto the product in a distinguished manner, such as laser printing manner, thus avoiding toxicity of printing pigment and scratch and realizing environmental protection.

Due to the tools sold on the market are very rough and are not delicate, we have designed a distinguished package so that our customers have amazing feelings when they receive our products. Preferably, this package can also protect our products from damage during shipping.